Special screws: special screw production method

Time:

2021-11-16

With the increase of transportation, energy and other infrastructure construction, in the tunnel, basement and slope, as a rock bolt technology to give full play to the self-stabilizing ability of rock mass has been developed rapidly, the amount of rock bolt is increasing day by day, showing broad prospects for development. Bolting is an economical and effective method to improve the stability of geotechnical engineering. Among them, the quality of the hollow anchor rod is reliable, the anchoring effect and reinforcement effect are much better, and its application is more and more extensive. Then, let's learn about the production method of the special screw together!

The special screw can ensure the water injection between the anchor body and the hole wall, and give full play to the anchoring effect of the anchor. The supporting force (pallet force and prestress) is provided immediately after the excavation of the bedrock, which effectively protects the inherent strength of the bedrock, prevents the loosening and deformation of the surrounding rocks, and improves the stability of geotechnical engineering.

The rod body is surrounded by sufficient slurry, and the resistance to corrosion is greatly improved, showing good durability. It can avoid or alleviate the occurrence of landslides, roof accidents and other engineering diseases, with significant durability and long-term hidden economic benefits. In the production equipment of anchor bolts, bolts should be specially designed, and there are also bolts that cannot meet the requirements of the existing technology.

The purpose of the special screw is to provide a special bolt, in particular a special bolt for the manufacturing process of the anchor rod. The technical solution of the utility model includes a rod, a bolt handle and a rod tail. The bolt handle is provided with a safety hole, and a grid is distributed on the bolt handle. The utility model adopts quenching heat treatment, has high thread strength and strong shear resistance, and is suitable for the production and processing of anchor rods.

The special screw has a screw and a screw head. The front end of the screw is fixed with a screw head. The surface of the screw, the screw head and the screw head is provided with a galvanized layer. The screw head is provided with an installation groove. The screw, the screw head, the screw head and the installation groove The intermediate shaft is located on the same straight line. The patented technology of the utility model has simple structure, low price and strong practicability. By setting the screw without thread, it has a certain positioning, which can be used for the positioning of the workpiece. Compared with the screw with the screw, it is not easy to loosen and has high fixability. By providing a slotted mounting slot, the screw can be installed and removed. By providing a galvanized layer, the surface of the screw can be smooth, easy to install, help prevent the screw from rusting, and improve the life of the screw.

The special screw solves the problem that the existing screw in the prior art cannot perform special fastening and fixing operations; by setting the screw without the screw, it has a certain positioning and can be used for positioning of the workpiece. Compared with screws with screws, it is not easy to loosen, has high fixability, and can be used for special connection and fixing operations. In order to solve the above problems, the special thread of the present technology is provided with a screw and a thread head, a thread head is fixed to the front end of the screw, a galvanized layer is provided on the surface of the screw, the thread head, the thread head and the thread head cover, and a mounting groove is provided on the thread rod and the thread head cover as one of the preferred embodiments of the present technology. As one of the preferred embodiments of the present technology, a chamfer is provided at a lower end of the screw, and an angle of the chamfer is.

As one of the preferred technical solutions of the present technology, the distances between two adjacent grooves are equal. As a preferred embodiment of the present technology, the mounting groove has a diameter of mm and a height of 0.1mm. The effect achieved by this technology is that by setting the screw with simple structure, low cost, high practicability, and no thread, it has a certain degree of positioning, which can be used for the positioning of the workpiece, and is not easy to loosen compared with the screw with a threaded rod., High fixation, able to complete special fastening and fixing work.

The above is the production method of special screws, if you need to know more, please feel free to contact us!

Related News

2024-06-13

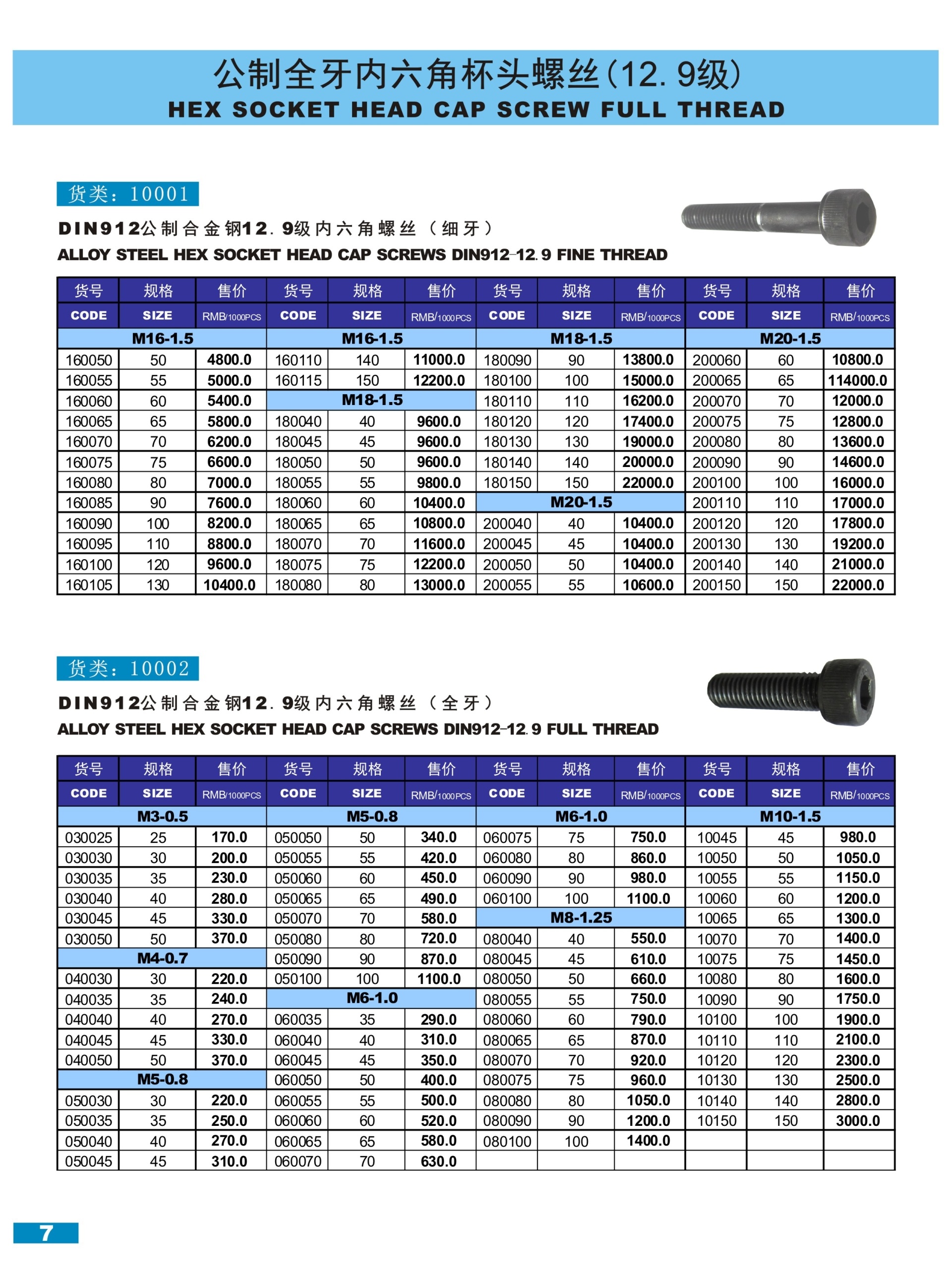

Huizhou Huihuachang Hardware Products Co., Ltd. is a professional fastener manufacturer specializing in the production, research and development and sales of fasteners. It is a large domestic manufacturer specializing in the production of 12.9-grade high-strength screws.

Contact Us

Address: Tongqiao Industrial Zone, Zhongkai High-tech Zone, Huizhou City, Guangdong Province

Telephone:+86-18948276082

Fax: 0752-3329498

E-mail:hua@hua-hz.com

©Copyright 2024 Huizhou Huihuachang Hardware Products Co., Ltd. All rights reserved.