What are the specifications and classification of special screws

Time:

2021-11-22

Special screw representation format: thread specification d = M12, nominal length L = 80mm, performance grade 4.8, equal-length double-headed stud, complete mark: GB 901 M12 × 80. So what are the specifications and classification of special screws?

Product example: Special screw studs usually require surface treatment. There are many kinds of surface treatment for special screws and bolts, such as electroplating, blackening, oxidation, phosphating, non-electrolytic galvanizing, etc. However, electroplated fasteners account for a large proportion of the actual use of fasteners. Especially widely used in automobiles, tractors, household appliances, instrumentation, aerospace, communications and other industries and fields. However, for threaded fasteners, it is not only required to have a certain anti-corrosion ability, but also to ensure the interchangeability of threads, which is also called screwing in here.

In order to meet the requirements of threaded fasteners in the use of "anti-corrosion" and "interchangeable" dual performance, the development of special plating coating standards is very necessary. The products are produced in strict accordance with ASTM A193 B7 b7m B8 b8m B6 B16 and A320 L7 l7m 8b b8m standards, with complete specifications and strong processing capacity.

Dimensional standards can be selected according to drawings: gb897, gb898, gb899, gb900, gb901, din938, din939, ifi136, double head, etc. There are A- type thick rod and B- type thin rod. Its optional materials:

1、 AISI4140、AISI4145

2、 AISI304/S30400、AISI316/S31600

3、 AIS410/S41000

4.Cr-Mo-V Alloy Steel

Special screw surface treatment: natural color, black, zinc plating (Zn, hdzn), nickel plating (Ni), cadmium plating (CAD), dacrometere coating, polytetrafluoroethylene (PTFE), fluoropolymer coating, etc.

Special screw optional materials: AISI304/s30400, AISI316/S31600 surface treatment: solid solution color, polytetrafluoroethylene (PTFE), YFLOORO (fluoropolymer) coating, etc.

Classification of special screws:

1. According to the force mode of connection, there are ordinary bolts and reaming bolts. Bolts for reaming should match the size of the hole and be used when subjected to lateral forces.

2. According to the head shape, there are hexagonal head, round head, square head, countersunk head, etc. Generally, the countersunk head is used where the surface is required to be smooth and no protrusions after connection, because the countersunk head can be screwed into the part. The round head can also be screwed into the part. The tightening force of the square head can be greater, but the size is larger. Hexagonal heads are commonly used.

In addition, in order to meet the need for locking after installation, the special screw head and rod have holes to prevent the bolt from loosening when subjected to vibration. Some special screws without threads should be thinned, which are called thin medium bolts. Such bolts facilitate variable force connections. There are special high-strength bolts on the steel structure. The head will be bigger and the size will change.

In addition, special screws have some special uses: T-slot bolts commonly used in machine tool fixtures have a special shape, and both sides of the head should be cut off. The anchor bolts are used to connect and fix the machine to the ground. There are many shapes, U-shaped bolts, such as the above and so on.

Related News

2024-06-13

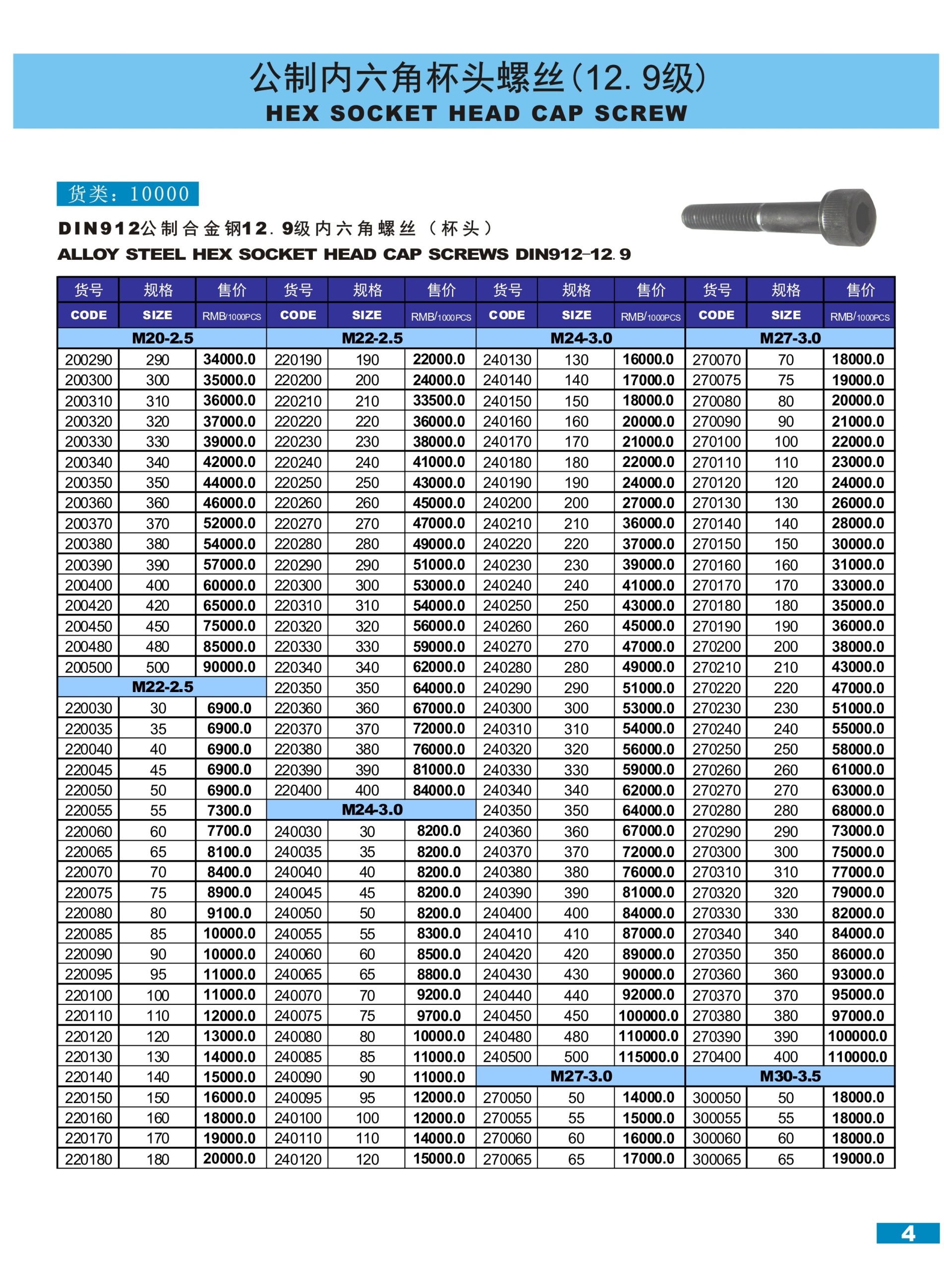

Huizhou Huihuachang Hardware Products Co., Ltd. is a professional fastener manufacturer specializing in the production, research and development and sales of fasteners. It is a large domestic manufacturer specializing in the production of 12.9-grade high-strength screws.

Contact Us

Address: Tongqiao Industrial Zone, Zhongkai High-tech Zone, Huizhou City, Guangdong Province

Telephone:+86-18948276082

Fax: 0752-3329498

E-mail:hua@hua-hz.com

©Copyright 2024 Huizhou Huihuachang Hardware Products Co., Ltd. All rights reserved.