How to deal with the loosening of special screws

Time:

2021-12-02

If some important items are fixed, it will be fatal when the special screws are loosened, not only worrying about life safety, but also worrying about property damage. Let's talk about the reasons for the loosening of special screws and how to prevent this worrying situation.

1. Fixed parts and equipment with vibration effect. Not long ago, when there was a report on the Internet about magical physical weapons such as "earthquake architectural relics", the editor was skeptical. It must be dangerous to install these things with expansion screws, and companies clearly know that this will produce vibration effects, so they should not use expansion screws to fix them. This could fall at any moment. This is the thing to do! It is not recommended to use special screws to install any equipment that has vibration effects. It is recommended to use expansion anchor bolts.

2. The nut is loose due to improper installation. If you are not a person who often installs special screws, you may miss one point, that is, when installing special screws, you should fully expand and tighten them until they cannot be tightened. Some people are afraid to twist the slider. It is recommended not to buy inferior special screws. If you install with pure national standard expansion screws, you don't have to be afraid. You have to screw it to a position where it can't be screwed!

3. Product quality problems caused by sliding buckles. This problem is all too common. This requires freedom of time and space. It's also a 10-cent expansion screw. Non-standard special screws shall be installed once, and sliding buckle shall be installed twice. Material, time and labor costs may exceed 30 cents. The result of buying low-quality products is a very simple solution. One-time purchase of pure GB expansion screws ~!

How to save a loose special screw?

1. Remove and reinstall the new special screws. It is a difficult job to remove the loose special screws. You need to see what an expansion screw looks like. If it is an external special screw, break it off with a hand drill and take it out. If it is an internal special screw, it is more convenient. Screw out with suction in the opposite direction. If not, please use a hand drill! In short, it is really difficult to remove the special screws that have been installed. This method is not recommended. It is recommended to cut and grind exposed parts with an angle grinder.

2. Stick it with fastening glue. Go to the place where you sell glue, ask if you sell anything to make the iron product safer, then lock it completely, and you need to do the follow-up work.

3. Re-punch the hole in another position and reinstall the new special screw. After flattening the last special screw with an angle grinder, select another position to re-drill. It is very important to re-drill, not too close.

Related News

2024-06-13

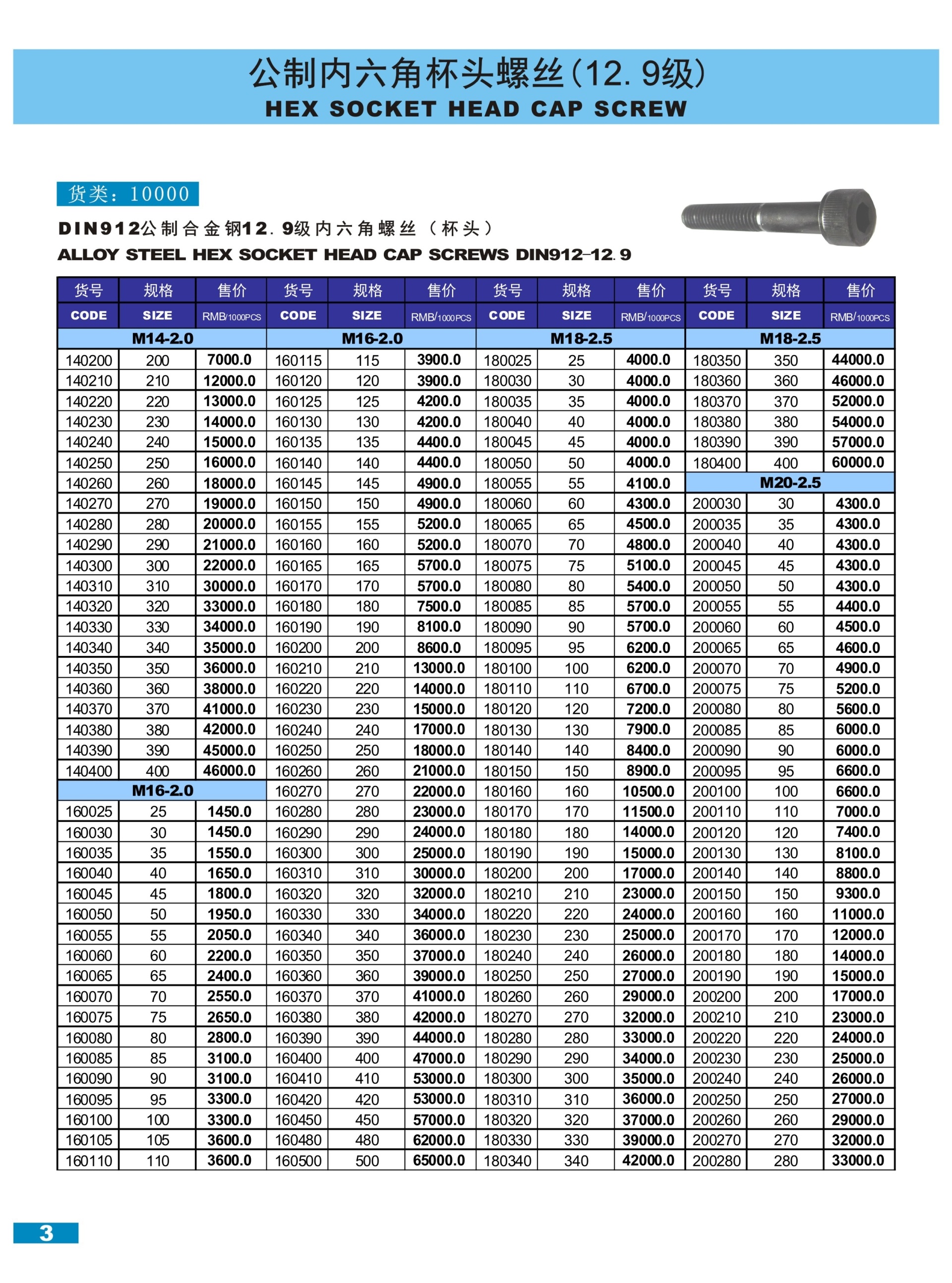

Huizhou Huihuachang Hardware Products Co., Ltd. is a professional fastener manufacturer specializing in the production, research and development and sales of fasteners. It is a large domestic manufacturer specializing in the production of 12.9-grade high-strength screws.

Contact Us

Address: Tongqiao Industrial Zone, Zhongkai High-tech Zone, Huizhou City, Guangdong Province

Telephone:+86-18948276082

Fax: 0752-3329498

E-mail:hua@hua-hz.com

©Copyright 2024 Huizhou Huihuachang Hardware Products Co., Ltd. All rights reserved.