Special screw production method

Time:

2022-01-27

The special screw is a special expansion bolt, which is a cast iron part produced by pouring technology. It is composed of two parts: cylinder and wedge iron. Because the existing special screws can expand too short, the pulling force that can be withstood is very limited. Bulging is completely different. It can expand the entire cylinder and completely close to the hole wall, so that the hole wall generates a huge and uniform expansion force, thereby firmly fixing the bulging screw in the hole. This screw can't be pulled out after one installation. Since the expansion performance is particularly excellent, the installation is also particularly easy.

If used in a place to be beautiful, it will be strong and beautiful. The appearance of this screw may abolish the existing expansion screw, so let's learn about the production method of the special screw!

1. the shortcomings of existing special screws.

The two existing special screw products have obvious disadvantages. The structure of an expansion screw is that there is a long screw rod in the middle of the, and a short thin-walled iron pipe is embedded on the outside. There are 4 short slots at the lower end of the iron pipe, and the lead screw above the iron pipe is provided with a flat buffer and a nut. The upsetting of the front end of the lead screw is conical. The larger diameter at the bottom of the cone is larger than the inner diameter of the iron pipe and smaller than the outer diameter of the iron pipe. When in use, tighten the nut and lift the screw upward, the cone will expand the thin-walled tube, thereby generating an expansion force on the hole wall, and the screw is fixed in the hole by the expansion force. In general, this expansion screw can withstand very limited pull-out forces, which is a fundamental disadvantage.

2. the excellent performance of special screws.

Special screws are all called "special expansion bolts". Its performance is completely different from the above two expansion screws. The screw can be expanded as a whole and close to the wall of the hole. The wedge iron produces a huge uniform expansion force and is firmly fixed in the hole. Because the expansion performance is particularly good, the installation is also very easy, the ability to resist drawing is several times higher than the previous expansion screw, and the shear resistance is also greatly improved. Once the bulging screw is installed, it cannot be pulled out again.

3. technical solution for making special screws.

Special screws are cast iron parts produced with pouring technology. It is composed of two parts: cylinder and wedge iron. The barrel is a thick-walled tube with several grooves of different depths in the horizontal direction on the outside. This is to remove ineffective materials, reduce weight, and increase the coefficient of friction. The upper tap of the inner wall acts as a nut. The aperture of the lower half of the inner wall is upper and lower small cones, and the same cone inverted cone trapezoidal wedge iron is arranged in the middle. The key technical measure is to open longitudinal grooves on the cylinder (the number of wire teeth is more than twice that of standard nuts, and the thread strength is sufficient, so the drawing ability is not affected. In this way, the cylinder has lateral elasticity and can expand freely.

Special screws are cast iron parts produced with pouring technology. It is composed of two parts: cylinder and wedge iron. The barrel is a thick-walled tube with several grooves of different depths in the horizontal direction on the outside. This is to remove ineffective material to reduce weight and increase the coefficient of friction. The upper tap of the inner wall acts as a nut. The inner hole diameter of the lower half is a small cone, and the inverted cone trapezoidal wedge iron with the same cone is arranged in the middle.

An important technical measure is to open a longitudinal groove on the cylinder, so that the cylinder has lateral scalability and can expand freely. When installing and using, use an iron rod of suitable thickness and length to press the lower end against the wedge iron, knock the iron rod with a hammer from above, and move the wedge iron downward until it is fully expanded. In this way, the outer surface of the bulging thread will generate a large and uniform bulging force on the inner wall of the hole, and the barrel of the bulging thread will be firmly fixed in the hole. This screw will become strong and beautiful when used in places with aesthetic requirements.

The above is the production method of special screws, if you need to know more, please feel free to contact us!

Related News

2024-06-13

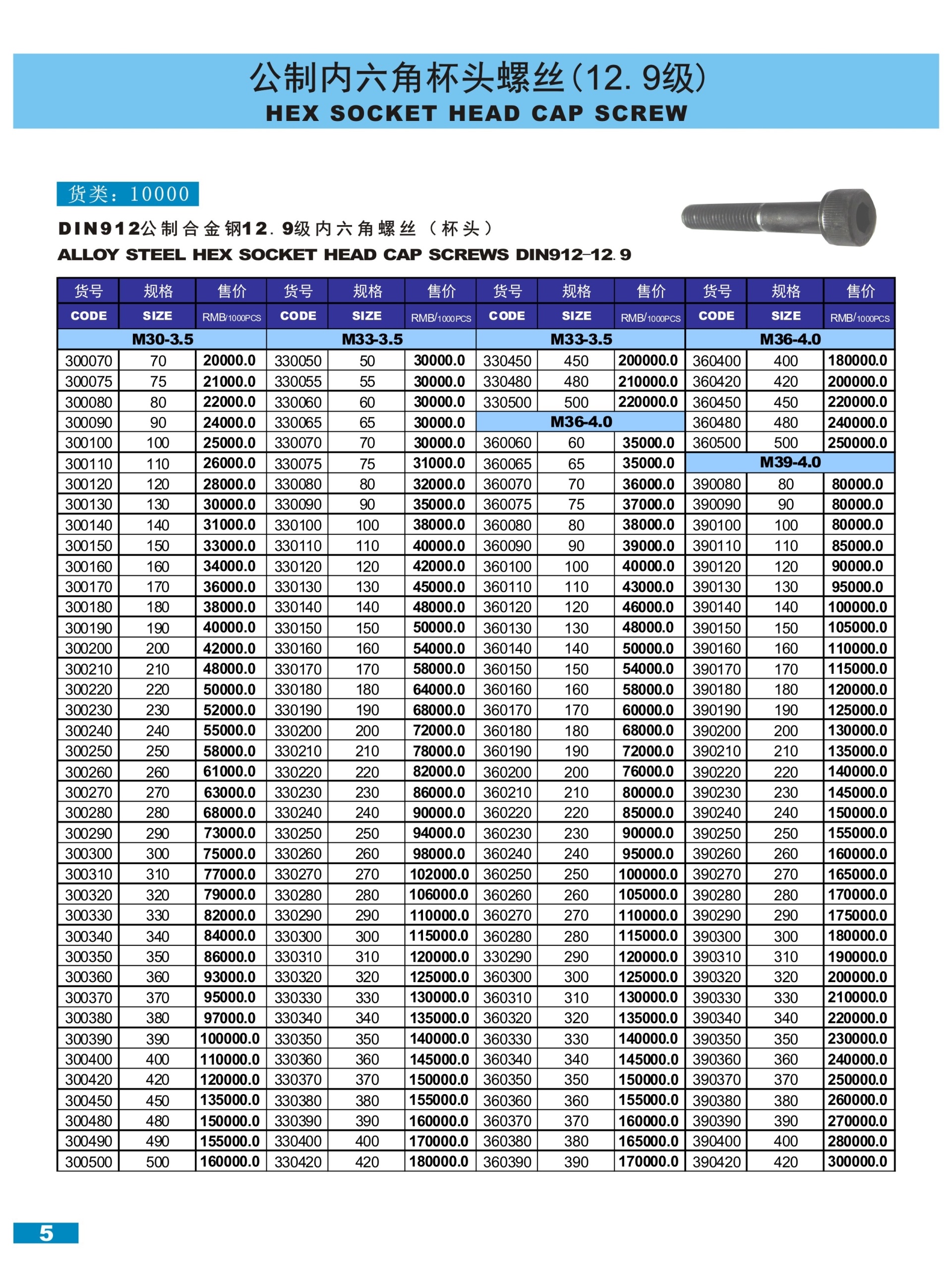

Huizhou Huihuachang Hardware Products Co., Ltd. is a professional fastener manufacturer specializing in the production, research and development and sales of fasteners. It is a large domestic manufacturer specializing in the production of 12.9-grade high-strength screws.

Contact Us

Address: Tongqiao Industrial Zone, Zhongkai High-tech Zone, Huizhou City, Guangdong Province

Telephone:+86-18948276082

Fax: 0752-3329498

E-mail:hua@hua-hz.com

©Copyright 2024 Huizhou Huihuachang Hardware Products Co., Ltd. All rights reserved.